Purpose

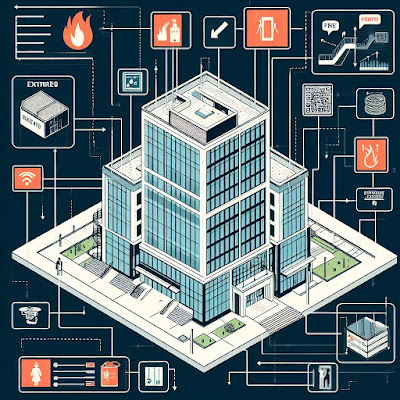

The purpose of this Fire Prevention and Protection Plan (FPPP) is to outline the company's approach to preventing and responding to fires in the workplace.

Scope

This FPPP applies to all employees, contractors, and visitors to the workplace.

Responsibilities

- Management: Management is responsible for developing and implementing this FPPP and for ensuring that all employees are trained on the plan.

- Employees: Employees are responsible for following the procedures outlined in this FPPP and for reporting any fire hazards to their supervisor immediately.

Fire Prevention

The following are some ways to prevent fires in the workplace:

- Keep work areas clean and free of clutter.

- Store flammable materials in properly labeled safety cabinets.

- Do not smoke in the workplace.

- Keep fire extinguishers in good condition and easily accessible.

- Conduct regular fire drills.

Fire Protection

The following is a fire protection plan for the workplace:

- Evacuate the building. If you see a fire or if you are aware of a fire, evacuate the building immediately. Follow the evacuation routes to the designated assembly area.

- Report the fire to your supervisor. Once you are safely at the assembly area, report the fire to your supervisor.

- Follow the instructions of emergency personnel. Once emergency personnel arrive, follow their instructions.

Specific Fire Protection Procedures

This FPPP should include specific procedures for responding to different types of fires, such as electrical fires, chemical fires, and grease fires.

The following are some general tips for responding to different types of fires:

- Electrical fires: If you see an electrical fire, unplug the appliance or machine that is on fire. If you cannot unplug the appliance or machine, use a fire extinguisher to extinguish the fire.

- Chemical fires: If you see a chemical fire, try to contain the spill with absorbent materials. If you are unable to contain the spill, evacuate the area and call for help.

- Grease fires: If you see a grease fire, do not throw water on it. This will make the fire worse. Instead, use a fire extinguisher or a smothering agent, such as sand or baking soda, to extinguish the fire.

Training

All employees should be trained on this FPPP. The training should cover the following topics:

- The different types of fires that can occur in the workplace

- The procedures for responding to each type of fire

- The location of the assembly area

- The location of fire extinguishers and other fire safety equipment

Review and Update

This FPPP should be reviewed and updated on a regular basis to ensure that it is effective and up-to-date.

Additional Considerations

The FPPP should be tailored to the specific needs of the company and its workplace. It is important to involve employees in the development and implementation of the plan to ensure that it is effective and easy to follow.

The FPPP should also be coordinated with the fire prevention and protection plans of local emergency services.

Conclusion

By following the guidelines in this FPPP, you can help to prevent and respond to fires in the workplace. This will help to protect yourself, your co-workers, and your property.

Comments

Post a Comment

Share with our industrial professional friends

Thank you for your valuable comment