A safety manual is a document that outlines the safety procedures and regulations for a particular organization or workplace. It is a valuable tool for preventing accidents and injuries, and it can help to create a positive safety culture.

A safety manual should include the following sections:

- Introduction: This section should provide an overview of the safety manual and its purpose.

- Hazard identification and assessment: This section should identify the hazards that exist in the workplace and assess the risks associated with each hazard.

- Control measures: This section should outline the control measures that are in place to mitigate the risks associated with the hazards.

- Safe work practices: This section should outline the safe work practices that employees should follow to avoid accidents and injuries.

- Emergency procedures: This section should outline the emergency procedures that employees should follow in the event of an accident or other emergency.

- Training: This section should outline the training that employees should receive on safety procedures and regulations.

- Reporting of hazards and incidents: This section should outline the process for reporting hazards and incidents to management.

- Enforcement: This section should outline the process for enforcing safety procedures and regulations.

The safety manual should be written in a clear and concise language that is easy to understand. It should be updated regularly to reflect changes in the workplace or in safety regulations. The safety manual should be distributed to all employees and should be accessible to them at all times.

By following the guidelines above, organizations can create a safety manual that will help to protect their employees and their bottom line.

Here are some additional tips for creating a safety manual:

- Get input from employees: Employees are the ones who are most familiar with the hazards in the workplace. Get their input on the safety manual to ensure that it is accurate and relevant.

- Use plain language: The safety manual should be written in plain language that is easy to understand. Avoid using jargon or technical terms that employees may not understand.

- Keep it concise: The safety manual should be concise and to the point. Don't overload it with information that employees won't need.

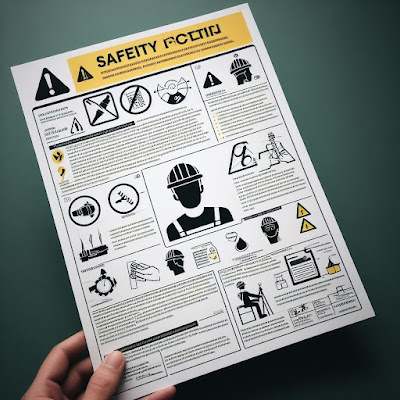

- Use visuals: Visuals can help to make the safety manual more engaging and easier to understand. Use pictures, diagrams, and flowcharts to illustrate the safe work practices and procedures.

- Update it regularly: The safety manual should be updated regularly to reflect changes in the workplace or in safety regulations.

- Make it accessible: The safety manual should be accessible to all employees at all times. Post it in a central location or make it available online.

By following these tips, organizations can create a safety manual that will help to protect their employees and their bottom line.

Here is a list of safety manual documents that organizations can include in their safety manual:

- Introduction

- Hazard identification and assessment

- Control measures

- Safe work practices

- Emergency procedures

- Training

- Reporting of hazards and incidents

- Enforcement

- Job Hazard Analysis (JHA)

- Safety Data Sheets (SDSs)

- Confined Space Entry Procedures

- Fire Safety Procedures

- Electrical Safety Procedures

- Chemical Safety Procedures

- Machinery Safety Procedures

- Material Handling Safety Procedures

- Workplace Ergonomics

- Personal Protective Equipment (PPE) Requirements

- Accident Investigation Procedures

Organizations can tailor the contents of their safety manual to the specific hazards and risks of their workplace. It is important to note that this list is not exhaustive, and organizations may need to include additional documents in their safety manual depending on their specific needs.

Good conceptiol theory

ReplyDeleteThank you

Delete